DL1000

ELT

| Availability: | |

|---|---|

| Quantity: | |

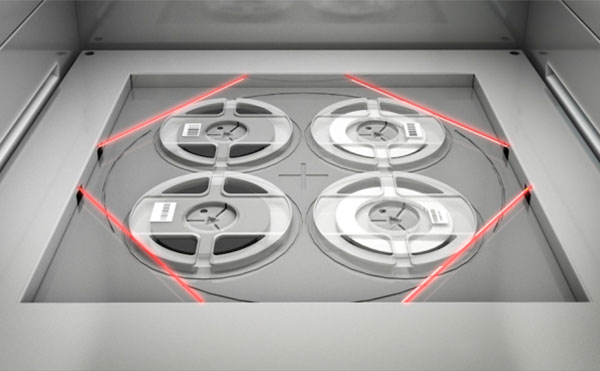

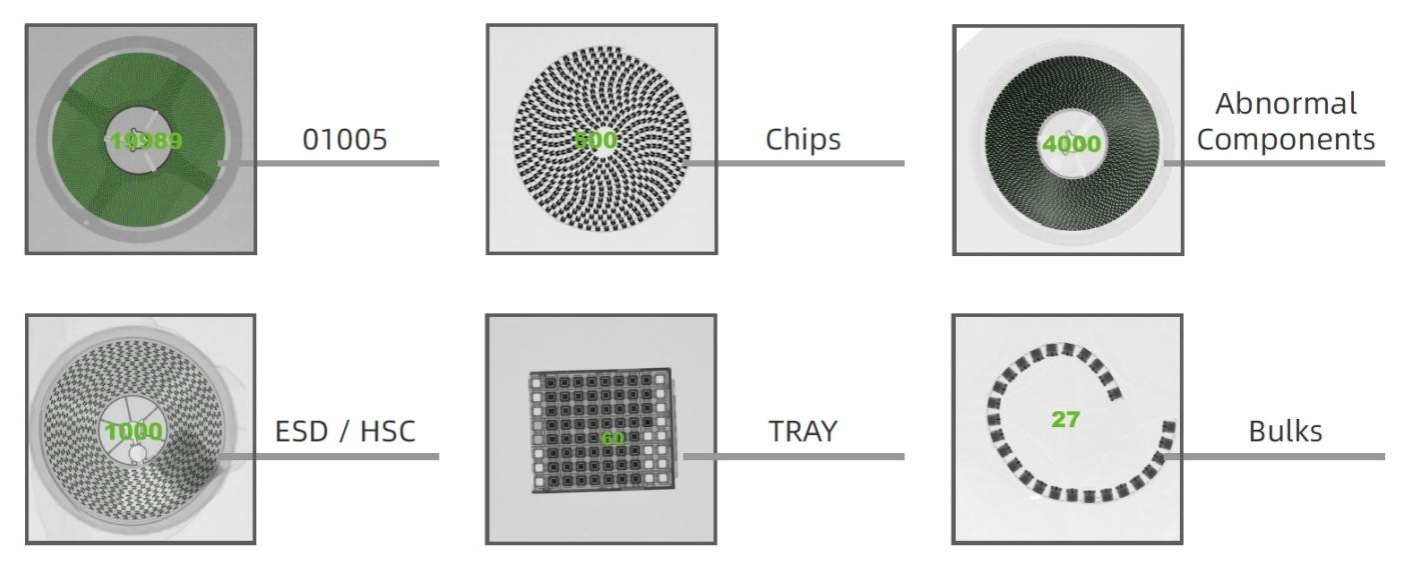

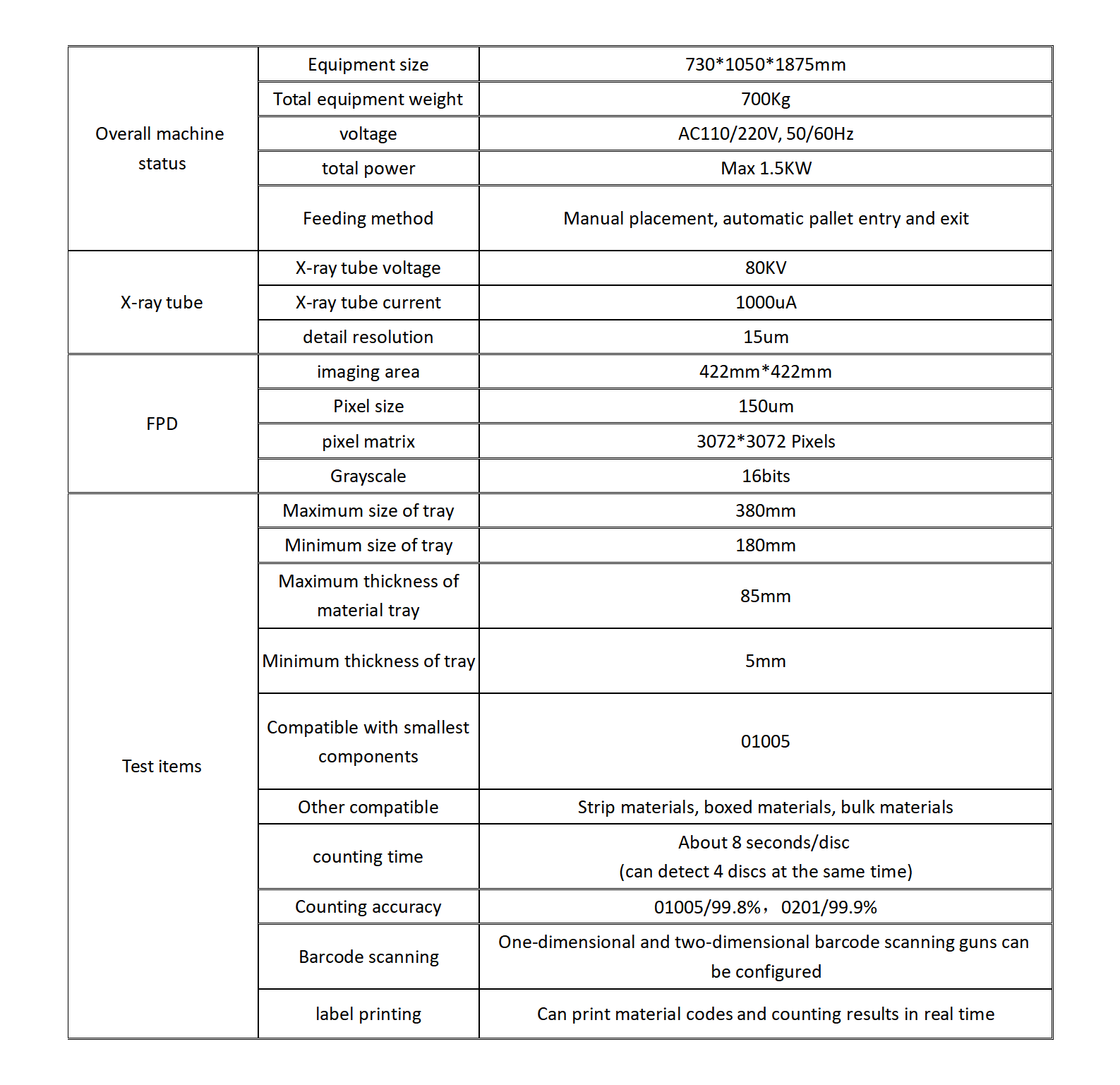

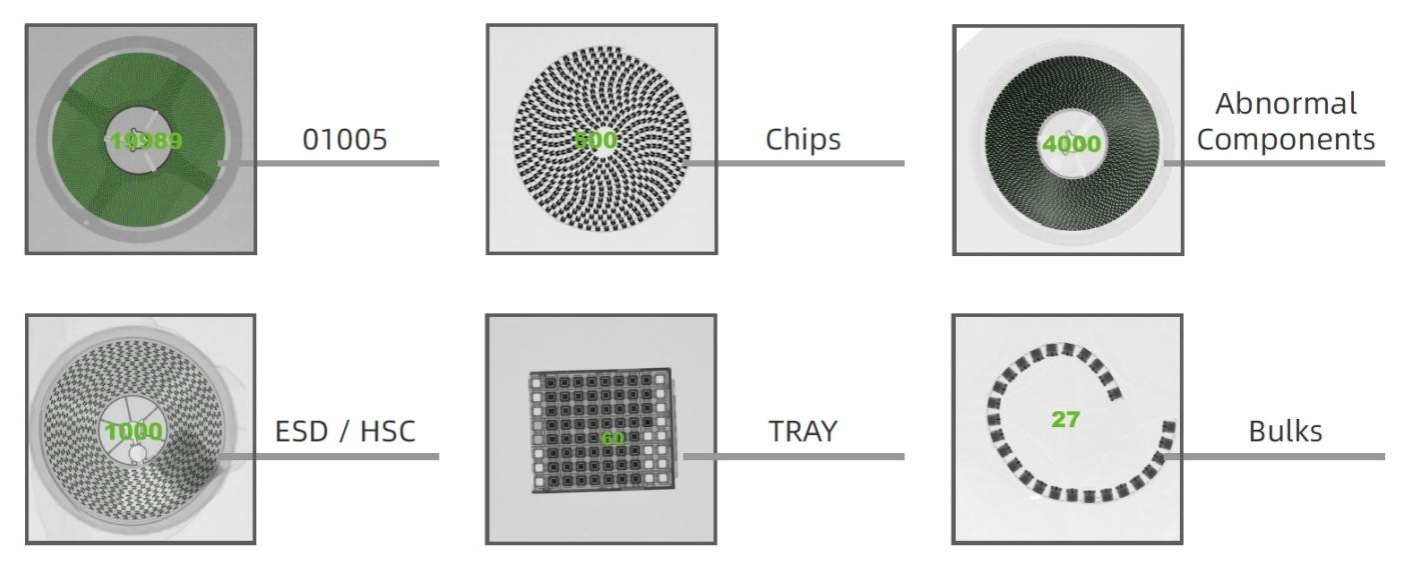

Used for the rapid increase of reel inventory for production in the SMT industry, testing components: resistors, capacitors, inductors, crystals, LEDs, diodes, transistors, multi-pin ICs and other common inventories covered in the industry.

1. The ray source adopts closed X-ray tube, which has stability, maintenance free and long life.

2. The X-ray receiver uses a 17-inch dynamic flat plate detector, with imaging block, no distortion and other characteristics.

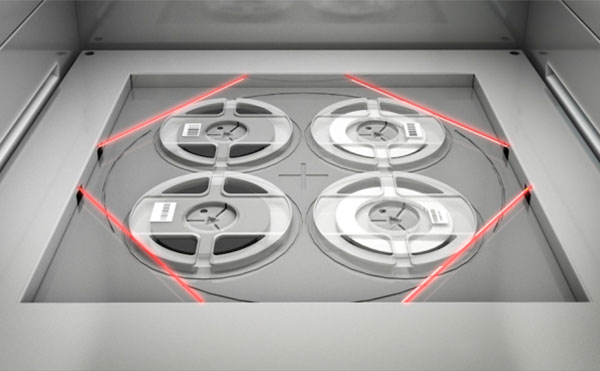

3. One 13-17-inch material disk or four 7-inch material disks can be calculated simultaneously.

4. Free to update and support of the algorithm and database permanently.

5. There is no need to spend 3-5 days to input the data into the material plate in the factory, and users can use it directly.

6. Support the automatic saving of SPC statistics, pictures and results in any format

7. Greatly reduce the counting time, avoid the extra manpower, and can turn to assist other personnel to collect or change the

8. lines, and shorten the line change and stop line time.

9. Digital data, can be printed barcode stickers or directly uploaded to the database, the traditional way of point material machine,

10. must continue each operator one

11. Take up a large space, the inventory results or manual fill in, may write wrong or missing write.

12. Do not open the packaging bag to maintain the integrity of the parts and will not affect the moisture resistance of the parts

13. Meet the trend of industry 4.0, SMT production line, intelligent, less human, efficient.

Note: The above information only represents general descriptions and characteristics, which may change with technological advancement and equipment upgrades. Specific parameters are subject to the final agreement.

Used for the rapid increase of reel inventory for production in the SMT industry, testing components: resistors, capacitors, inductors, crystals, LEDs, diodes, transistors, multi-pin ICs and other common inventories covered in the industry.

1. The ray source adopts closed X-ray tube, which has stability, maintenance free and long life.

2. The X-ray receiver uses a 17-inch dynamic flat plate detector, with imaging block, no distortion and other characteristics.

3. One 13-17-inch material disk or four 7-inch material disks can be calculated simultaneously.

4. Free to update and support of the algorithm and database permanently.

5. There is no need to spend 3-5 days to input the data into the material plate in the factory, and users can use it directly.

6. Support the automatic saving of SPC statistics, pictures and results in any format

7. Greatly reduce the counting time, avoid the extra manpower, and can turn to assist other personnel to collect or change the

8. lines, and shorten the line change and stop line time.

9. Digital data, can be printed barcode stickers or directly uploaded to the database, the traditional way of point material machine,

10. must continue each operator one

11. Take up a large space, the inventory results or manual fill in, may write wrong or missing write.

12. Do not open the packaging bag to maintain the integrity of the parts and will not affect the moisture resistance of the parts

13. Meet the trend of industry 4.0, SMT production line, intelligent, less human, efficient.

Note: The above information only represents general descriptions and characteristics, which may change with technological advancement and equipment upgrades. Specific parameters are subject to the final agreement.